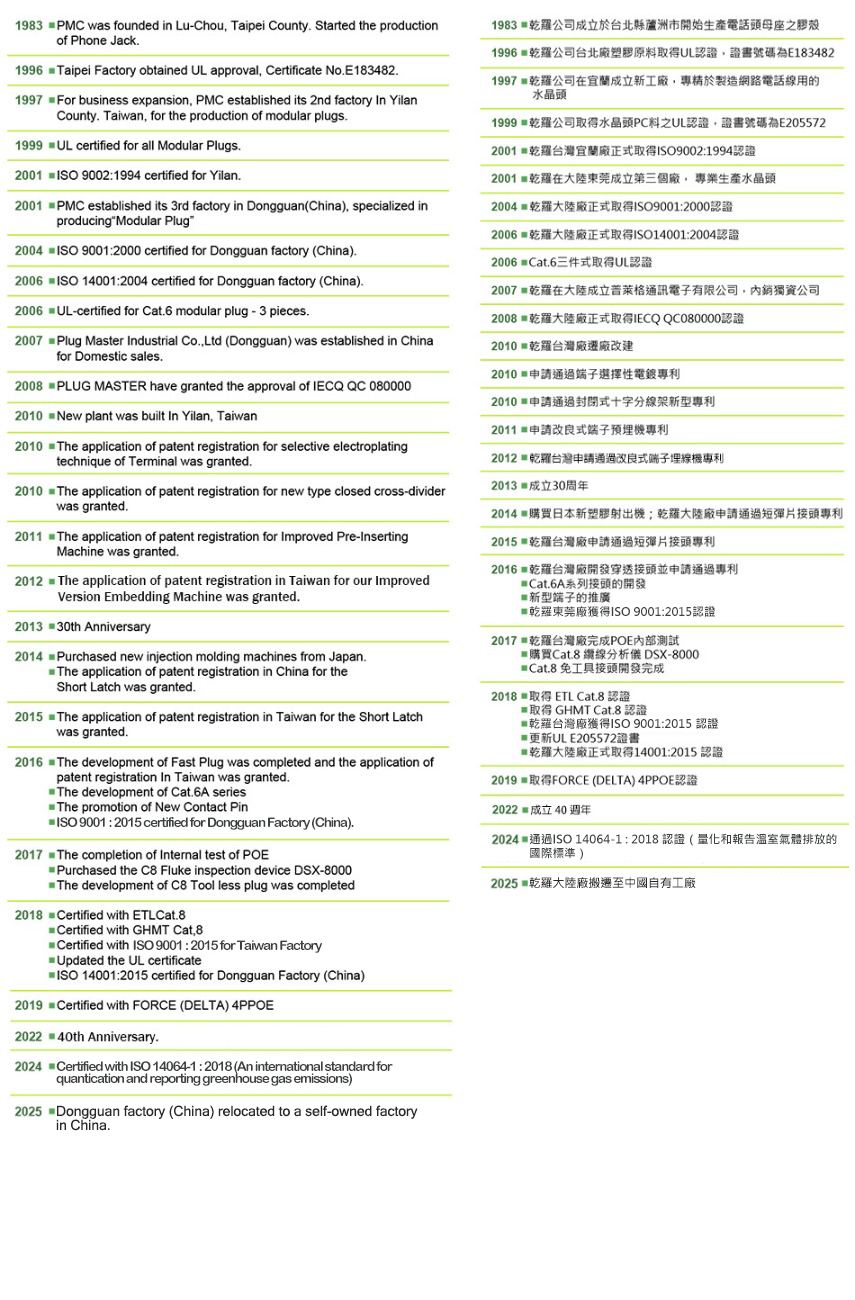

About Us

Company Profile

Plug Master Industrial Co., Ltd (PMC/ 乾羅科技股份有限公司) is a

Taiwan-based OEM and ODM RJ45 connector manufacturer (B2B),

established in 1983, and is designed to meet the demands of modern networking,

telecommunications, and industrial applications.

All of our products are strictly made to comply with international standards

such as ISO9001, ISO14064-1, ISO14001, and are compliant with REACH, and RoHS.

We offer a complete portfolio of RJ48/RJ45/RJ11/RJ12/RJ9....modular plugs,

ranging from Cat.5e to Cat.8, and from 4P4C to 15P15C. We have been producing a

variety of plugs to fit different copper patch cords and telephone cables.

PMC has maintained long-term partnerships with more than 150 customers from

over 50 countries across Europe, America, Australia, Asia, and Middle East.

We can provide strong technical support and technical instructions for cable

assembly to help customers achieve the highest performance of patch cords. Our

rich product knowledge can help customers select the right product more

accurately.

PMC 's product manufacturing process has been relatively matured over the

years. We are the Modular Plug leader in both production efficiency and quality

stability. Not only in "RJ plugs", PMC also provides the professional

crimping tools, and is committed to developing a single tool to suit all PLUG

specifications.

As to the PLUG BOOTs, we request the best compatibility with PLUGs, which must

be well-fixed and of high quality.

PMC 's packaging process has gradually replaced manual labor with

automated production. Not only can it complete the entire process from

production to packaging so that customers can directly put the goods on the

shelves after receiving them, but we can also offer various customized bags,

paper boxes, bubble packs and tool boxes.

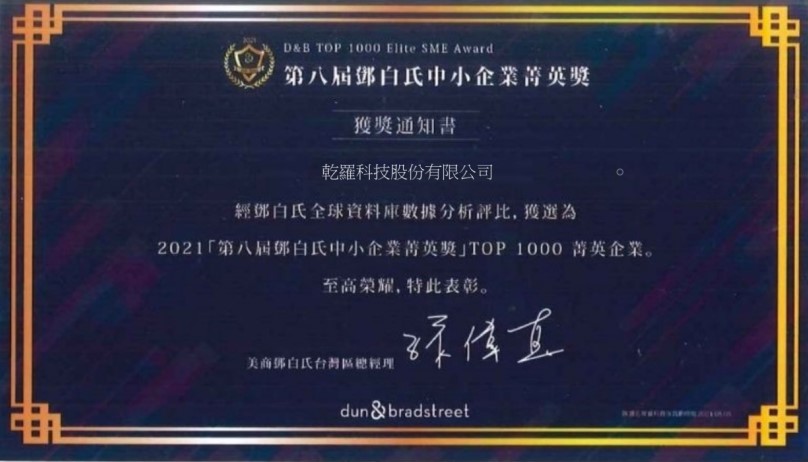

PMC has been committed to meeting customer requirements and to achieving

customer satisfaction as its goal.

We are proud to be the manufacturer with the most complete product range, the

fastest production efficiency, and the best quality in the Taiwanese industry.

Capabilities :

- Research and Development: Specializing in mold design, we develop customized solutions tailored to client specifications.

- Manufacturing Excellence: Utilizing precise, fully automated plastic injection and terminal assembly processes, we ensure high efficiency and superior quality in all our products.

- Quality Assurance: Our products are UL certified, and our factory holds ISO 9001, ISO 14001, and QC080000 certifications, reflecting our commitment to quality and environmental standards.

Our Core Products :

- RJ45 8P8C Connectors: Supporting Cat.5e, Cat.6, Cat.6A, and Cat.8 standards.

- RJ12 6P6C Connectors

- RJ11 6P4C & 4P4C Connectors

- Modular Plug Boots

- Telecommunication Networking Crimping Tools

Customization Services :

- We excel in producing RJ connectors across a wide range of specifications, tailored to meet diverse customer cable requirements. Our expertise in custom connector manufacturing allows us to provide solutions that align with specific client needs, ensuring both functionality and reliability.

Commitment to Excellence :

- Our focus extends beyond delivering high-quality connectors; we are dedicated to providing exceptional customer service and competitive pricing. As a leading manufacturer in our field, we have a proven track record of success and innovation.

We welcome your inquiries and orders, offering comprehensive technical support to fulfill your needs, from standard products to the most advanced custom requests.

For more information, please visit our website: https://www.plugmaster.com.tw

| Taiwan Factory : |

|

| China Factory : |

|

|

|

Our Facilities Environment

Test Profile

| The Profile Of Plugs Electrical Test |

| Our plugs have been approved by UL and meet with F.C.C standard specifications . Plugs are suitable for stranded and solid wire 24-26AWG |

| Electrical Test: |

| Energize plug 500 volts AC lasting 1 second |

| A.Insulation Resistance:500 M abohm. |

| B.Termination Resistance : 35 M abohm (MAX). |

| Gold Plate Inspection : |

| A.According with MIL-G-45204C Type I and ASTM Type 2 standards specification ( 99.7% pure gold Min ) |

| B.Grade D in standard of ASTM (Knoop hardness range > 200 Hk ) |

| C.Grade D in standard of MIL-G-45204 (Knoop hardness range > 200Hk) |

| D.Class 1 (50 microinches thickness minimum ) |

| The Gold-Plated Testing Instruments : |

| FISCHER SCOPE XULM-SYM |

| Mechanical: |

| A.The tensile strength of cable to plug is 7.7 Kgw . |

| B.Breakdown test : 2000 mating cycles. |

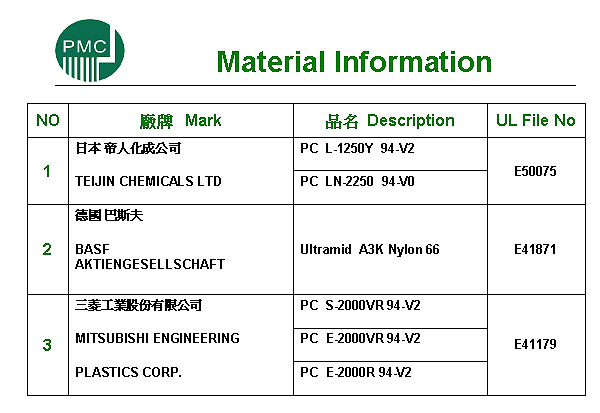

| Material and Surface Plating: |

| Housing Material : Polycarbonate 94V-0 ; 94V-2 (Fireproofing) |

| Contact blades : High strength cooper alloy is according with CNS9503 ,JIS 3110 and C5191R-H standards specification . |

| 100-120 microinches nickel under plated gold . |

| Operation Temperature: |

| - 10℃ ~60 ℃ |

Management System

IECQ QC 080000:2005 (2011/01/15 – 2014/01/14)

IECQ QC 080000:2012 (2014/01/15 – 2017/01/14)

UL-94V0 (LN-2250) & UL-94V2 (L-1250Y) – ROHS

UL-94V0 (LN-2250) & UL-94V2(L-1250Y)- REACH

PVC MATERIAL TEST REPORT( TSCA COMPLIANT) – UL-94V0 (3MTB030GF6001)

PVC MATERIAL TEST REPORT ( TSCA COMPLIANT) – UL-94V2 (3MTB055GF6001)

TSCA COMPLIANT DECLARATION FOR PVC PLUG BOOTS

Plug Master - All RJ Plugs TSCA Compliant Test Report (ETR24800596)

Plug Master - PVC Boots TSCA Compliant Test Report (ETR24800595 )

Plug Master - PVC PLUG BOOTS with PFAS standard Compliant

Plug Master - All RJ PLUGS with PFAS standard Compliant

(5) Prohibit the Use of Conflict Minerals Declaration

Statement of no use of "Conflict minerals"

On August 22, 2012,The US Securities and Exchange Commission (SEC) passed

Article No. 1502 of the "Dodd-Frank Wall Street Reform and Consumer Protection

Act", the final edition with regard to "Conflict minerals" procurement. With our

corporate social responsibility and international justice practice, ATEN

addresses our statement with the standardized self-management approach to avoid

use of metallic materials such as, gold, tantalum, tungsten, tin, etc, which are

often used in electronic products, from the conflict area such as Democratic

Republic of the Congo and its neighboring areas where environment and human

rights are neglected per the EICC/GeSI Conflict Minerals Reporting Template of

the Electronic Industry Citizenship Coalition (EICC).

PMC's Statement of "Conflict Minerals":

PMC and its suppliers shall take social and environmental protection

responsibilities.

The "Three No" principle for ATEN is no support, no acceptance and no use of

metals, i.e., "Conflict Minerals" from the D.R. Congo and its neighboring

nations as well as armed conflict areas where metals are mined illegally from

unacceptable working environments.

Suppliers shall retrace the sources of Co, Au, Pd, Ta, Sn and W that are

contained in all products to ensure that those metals do not come from the

"conflict mining areas".

Implement the green supply chain to comply with customer's requirements and

international justice practice. Understand in-depth the management condition of

the conflict minerals by suppliers and investigate per the EICC/GeSI Conflict

Minerals Reporting Template.

Our Patents

Letter of Patent

Patent of new type closed cross-divider (Dongguan Factory)

Patent of the structure of modular plug (Dongguan Factory)

Patent of the structure of modular plug (Taiwan Factory)

Patent of the improved modular plug (Taiwan Factory)

The Patent of special cutting design for Crimping tool (Taiwan factory)

The Patent of RJ45 8P8C Plug with short latch P8-039-9 (Taiwan factory)

The Patent for Extraction prevented Plug P8-039-9 + key P8-I040 (China factory)